Kohler Takes Top Honors in Mission Critical Top Tier Product Awards

Kohler Power is celebrating its latest achievement for its work in advancing sustainability for backup power generators. Mission Critical recently named Kohler the winner in its Generator category for the 2022 Top Tier Products Awards.

In addition to backup power providers, the annual awards recognize companies that provide critical infrastructure to data centers, including design and construction materials, IT equipment, HVAC systems, software solutions, infrastructure, and security systems. As Mission Critical writes, “‘Technological innovations designed to save energy’ are the inspiration behind the Top Tier Product Awards.”

Kohler’s Innovative Generator Technology

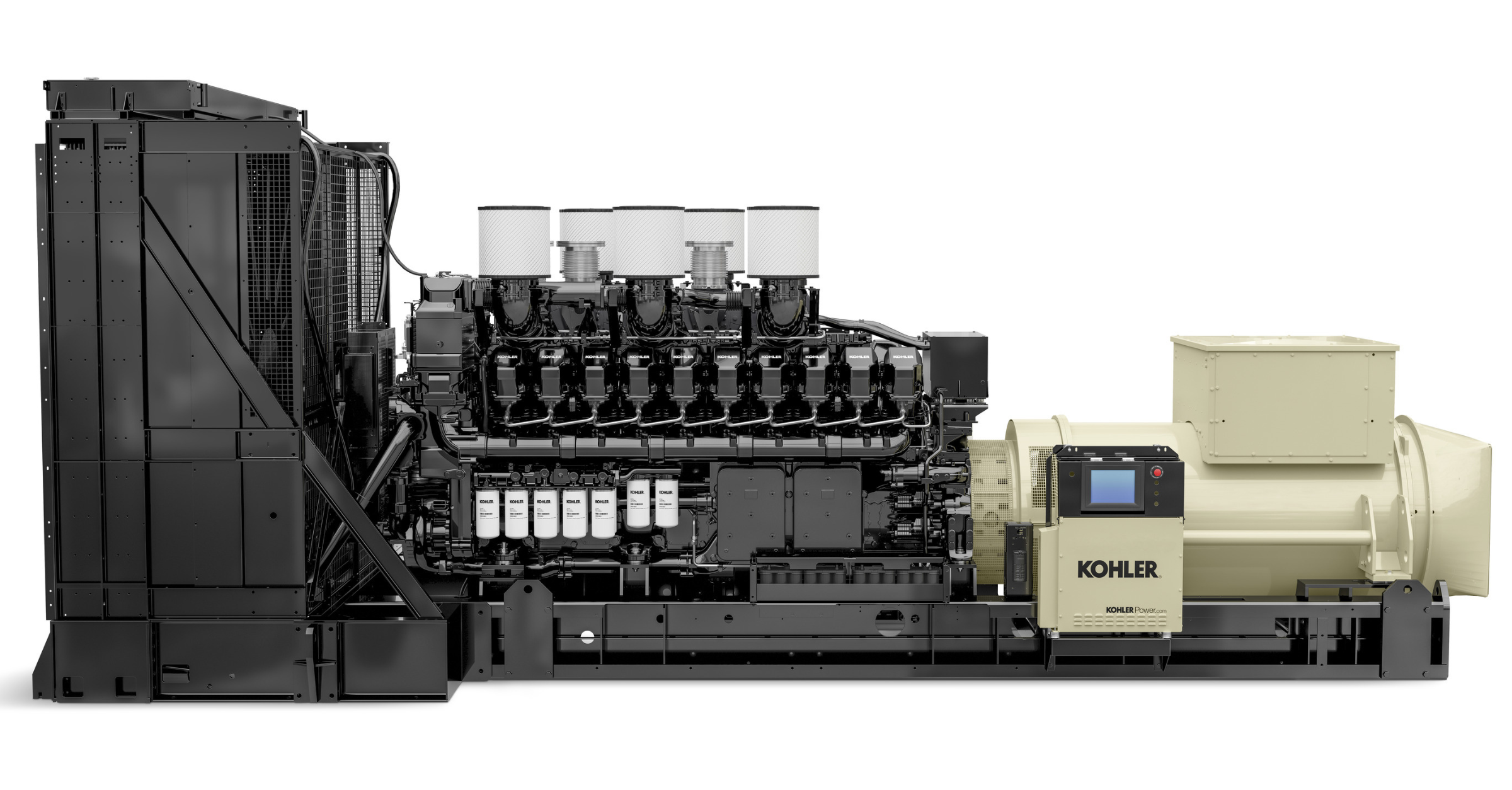

Kohler was recognized for its Tier 4 Final KD Series Generator, which provides a key advantage over traditional systems. The innovative new generator technology provides minimal maintenance demands for optimized continuity and maximized ease for users — all while meeting strict EPA-controlled sustainability requirements.

The KD exhaust aftertreatment technology eliminates the need for diesel particulate filters and diesel oxidation catalysts, resulting only in harmless exhaust byproducts like nitrogen and steam. Meanwhile, the KD series engine control units and integrated sensors continually monitor and control all elements of the exhaust aftertreatment system, delivering best-in-class emissions technology.

The Kohler team developed the KD Series Generators with the EPA’s focus on reducing six common pollutants (ozone, particulate matter, carbon monoxide, nitrogen oxides, sulfur dioxide, and lead) in mind. These areas of focus have led to increasingly stringent emission level standards.

Pollutants associated with diesel engine exhaust are a challenge for mission-critical generators that data centers rely on to keep their customers online in the event of unplanned outages. As power demands grow, demand for generators increases, making their sustainability of the utmost importance. However, most diesel generator strategies require multiple aftertreatment devices to meet requirements of each individual air pollutant. Of the six EPA pollutants, particulate matter (PM) and nitrogen oxide (NOx) emissions are often the most difficult to address.

PM forms from the partial combustion of diesel fuel in cooler parts of the cylinder, while NOx is the result of high cylinder temperatures oxidizing nitrogen in the air. Unfortunately, this creates an inverse relationship when it comes to in-cylinder engine management for performance and emissions — typically, harmful pollutants are created no matter what changes are made.

To address this industry challenge, Kohler ran a recent study concluding that some of today’s diesel generators can be safely run at 30% of the rated capacity or higher, as little as once per year, as opposed to once per month. This is all while maintaining optimal performance and staying within emissions guidelines. In fact, the savings from switching from monthly to annual loaded testing were compelling, with tests showing an 82% reduction in total pollutants emitted.

Generators and a Sustainable Future

Kohler’s commitment to sustainability is gaining momentum. In addition to researching ways to reduce diesel emissions, the company also announced its entire offering of generators is compatible with Hydrotreated Vegetable Oil (HVO), a cleaner-burning source of renewable energy. Moreover, the company was recently recognized by Fast Company for its sustainability innovations.

While the Kohler team has been placed in the spotlight for its innovations in generator technology, their focus is firmly on the future and finding even more ways to increase efficiency while maintaining the highest possible performance standards.

Check out Kohler’s full Mission Critical 2022 Top Tier Products submission here.